Planned Maintenance System

Safe and Efficient Ship Management

Streamlined Asset Tracking, Predictive Maintenance, and Compliance for Optimal Vessel Performance

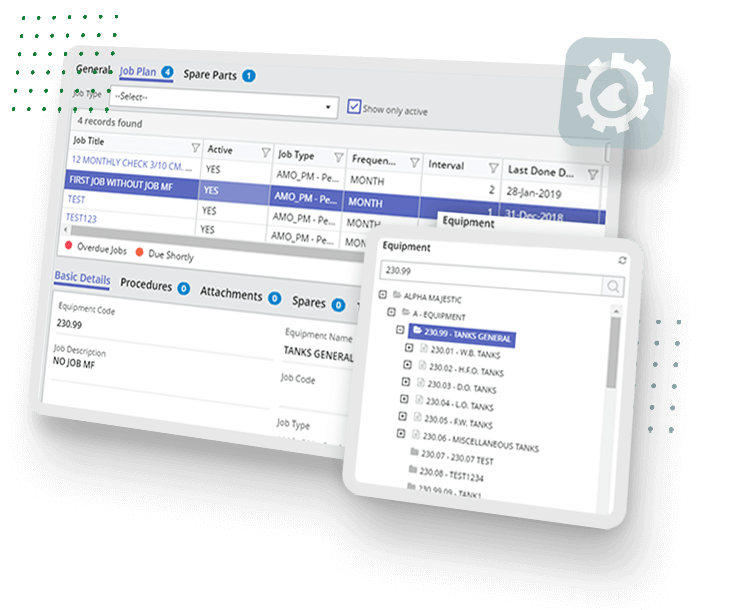

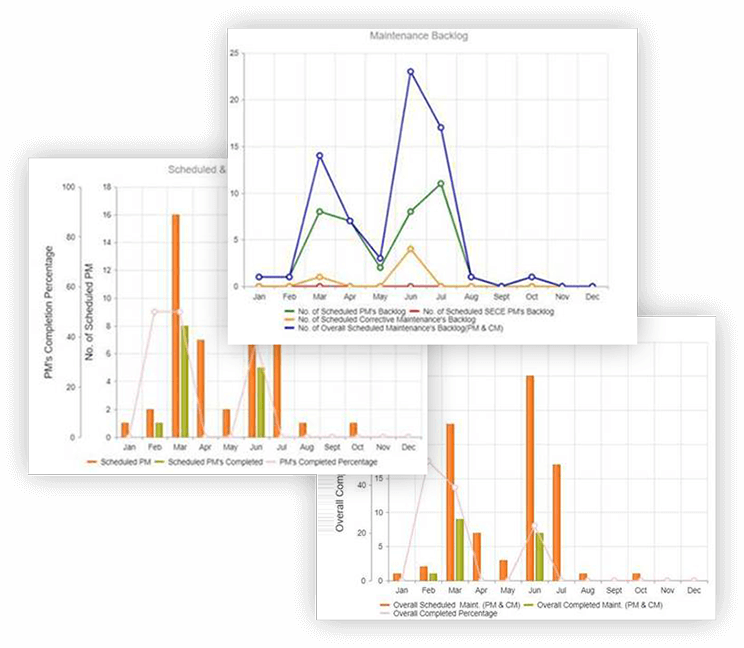

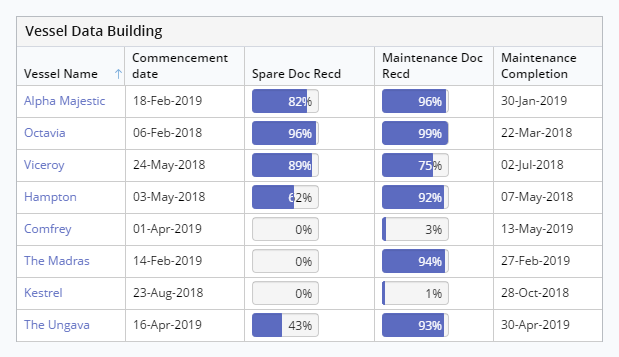

Our maritime Planned Maintenance System delivers tracking of assets, assemblies, and spare parts associated with vessel installations. The DNV type approved product can be configured according to manufacturers’ or Class requirements. The module features include pre-planning and scheduling of jobs with cost and time projections. Pre-planning capabilities offer resource, time, and spares planning, which play a critical role in inventory management based on predictive and preventive ship maintenance routines.

The Maintenance module aims to improve workplace safety and reliable vessel operations by allowing ship owners and managers to plan, execute, and document vessel-planned maintenance activities while complying with Class and manufacturer requirements. The PMS is adapted according to vessel type and Class, as well as any other requirements and measures, to effectively meet safety and environmental standards.

Other Products

Drydock

Dry Dock is a comprehensive drydock processing system, integrating all the processes in drydock for reliable operations.

Data Library

The Data Library module allows you to import data effortlessly facilitating job planning and streamlining job processes.