Efficient Drydock Management with Streamlined Drydock Software

Efficiently Integrate and Manage Ship Docking Operations Worldwide

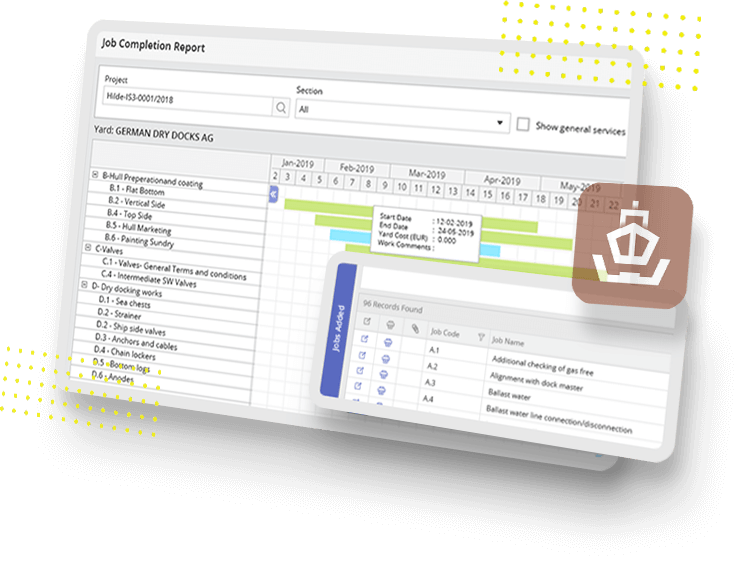

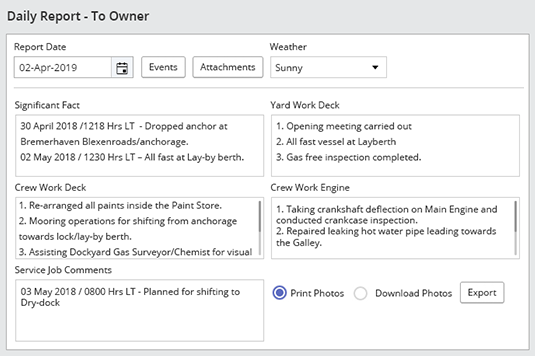

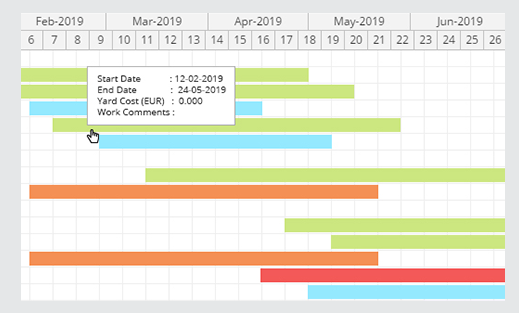

A drydock software that consolidates all associated procedures into a single integrated system that provides a standardized method for dry dock planning. It offers both required and necessary dry dock functionalities implemented in the system for smoother operations. The seamless integration of smartPAL modules such as Procurement, Accounts, and Maintenance ensures an efficient workflow from defect job tracking to dry dock specification building.

Enables seamless planning and organizing of all aspects of a ship’s docking. Facilitates every step from planning through repair work providing an intuitive system for smoother operations in dry docks.

Other Products

Maintenance

Our Planned Maintenance System offers a full data library of vessel equipment, spares, and jobs managed in a centralized setup, simplifying moving spares between ships.

Data Library

The Data Library module allows you to import data effortlessly facilitating job planning and streamlining job processes.